service line:400-680-8962 +86-13953623913

Product introduction

This product is a strong cationic quaternary ammonium salt polymer color removal flocculant, easy to dissolve in water, safe, non-toxic, good hydrolysis stability, PH change is not sensitive, has anti-chlorine.The freezing point is about -2.8℃, the specific gravity is about 1.04 GCM, and the decomposition temperature is 280-300℃.This product not only to the hydrophobic disperse dye decolorization effect is excellent, but also to the hydrophilic dye decolorization effect is also excellent, the amount is small, decolorization is obvious, the settling speed is fast, the processing liquid clarity is high, but also to reduce the COD composition, improve the COD removal rate.

Product indicators

Appearance: colorless to light yellow viscous liquid

Solid content: 40% ±1

PH: 4.0 to 7.0

Viscosity (25℃), CPS: > 70000

Use of the product

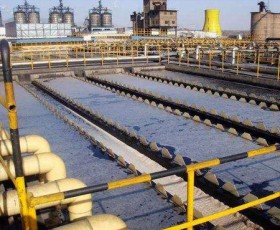

The industrial waste water discharged from dyeing and paper mill is dark in color.This product is a combination of decoloration, flocculation and COD degradation components. It has good comprehensive effect and low cost for decoloration.

Usage

Sequence of procedures depends on treatment process and test

A. Wastewater pretreatment

Neutral PH is adjusted by hydrated lime

B. Solution configuration

1. Start stirring in the inorganic flocculant configuration kettle, slowly pour poly aluminum chloride into the water, stir fully, and prepare 5% poly aluminum chloride solution.

2. Turn on the organic flocculant configuration kettle stirring, slowly put dyeing wastewater decolorizer into the water, fully stir, configured into 3% decolorant solution.

C. Decolorization (water temperature 15-30℃)

1. Open the sewage treatment tank for stirring at a high speed. Add 5-15kg of the above polyaluminium chloride solution while stirring.

2. Reduce the stirring speed and add 2-10kg of the above decolorant solution while stirring.

Stir on a low speed for a while

4. Let stand for

Packaging and storage

PE plastic drum 125kg.Sealed packaging, sealed storage, avoid contact with oxidant.

Valid for two years, it can be transported as non-dangerous goods.

back to the top